Decoding "Engine Iran": From Aviation Overhauls To Indigenous Power

The term "engine iran" might evoke different images depending on your background. For some, it immediately brings to mind the intricate world of aircraft maintenance, specifically a highly specialized type of engine overhaul. For others, it points to a nation's ambitious journey towards self-sufficiency in manufacturing advanced powerplants. This article delves into the multifaceted meaning of "engine iran," exploring its technical implications in aviation and its strategic significance in Iran's industrial landscape, while also briefly touching upon other interpretations to provide a comprehensive understanding.

Understanding the nuances behind "engine iran" is crucial, whether you're an aviation enthusiast, an industry professional, or simply curious about global technological advancements. We will explore how specific engine overhaul procedures, often referred to as "iran'ed," contribute to the longevity and safety of aircraft, and simultaneously examine Iran's domestic efforts to produce a range of engines, from pioneering jet engines to robust diesel powerplants for commercial vehicles. This dual perspective offers a unique insight into a term that holds both technical precision and national aspiration.

Table of Contents

- Introduction to "Engine Iran": A Dual Interpretation

- The Nuance of "Engine Iran" in Aviation Overhauls

- Iran's Drive for Indigenous Engine Manufacturing

- The Role of Private Sector and State Enterprises

- Navigating Challenges: Sanctions and Sustainability

- Beyond Physical Engines: A Note on "Search Engine Iran"

- Conclusion: The Enduring Power of "Engine Iran"

Introduction to "Engine Iran": A Dual Interpretation

The phrase "engine iran" carries a fascinating duality. In the specialized world of piston aircraft engines, particularly in North America, "iran" can refer to a specific type of engine overhaul or inspection, distinct from a full "zero-time" rebuild. This usage often implies a thorough inspection and replacement of worn parts without necessarily returning the engine to a "new" status for logbook purposes. For example, the data mentions an instance where an FBO's insurance paid to "have the engine iran'ed by mattituck (back when that was a good thing)," suggesting a recognized, albeit perhaps now less common, service. This contrasts sharply with the other, broader interpretation of "engine iran," which refers to the development and manufacturing of engines within the nation of Iran itself. This latter meaning encompasses a wide array of engines, from advanced jet engines to heavy-duty diesel powerplants, symbolizing Iran's push for technological self-reliance. Our exploration will navigate both these significant interpretations, highlighting their unique contexts and implications.The Nuance of "Engine Iran" in Aviation Overhauls

In the realm of general aviation, maintaining an aircraft engine is paramount for safety and operational longevity. The term "engine iran" in this context refers to a specific type of overhaul or inspection process that falls short of a complete "zero-time" factory overhaul or rebuild. Instead, it implies a thorough check-over and replacement of components that have exceeded their tolerances or show significant wear, without necessarily resetting the engine's time in service to zero. This approach is often a pragmatic decision driven by cost, component life, and the specific findings during an inspection. For instance, the data indicates that an engine that had a gear up/prop strike was "checked over pretty thoroughly, and had all the seals replaced as part of that work." This kind of detailed inspection and component replacement, without a full "zero-time" designation, aligns with the practical implications of an "engine iran" process.The Cost-Benefit Analysis of Engine Overhauls

Deciding on an engine overhaul is a complex financial and safety decision for aircraft owners. A full factory overhaul or a "zero-time" rebuild can be prohibitively expensive. This is where the concept of an "engine iran" comes into play as a potentially more cost-effective alternative. The data highlights significant cost factors: "Just overhauling the magnetos alone would contribute $1400 to the engine overhaul cost." This illustrates that even individual component overhauls add up. Furthermore, the decision to overhaul specific parts rather than replace them entirely is a key aspect. "With the iran decision comes the ability to get another 200+ hours out of these parts," suggesting that this type of overhaul aims to extend the life of existing components, offering a practical solution for owners looking to maximize value without incurring the full expense of a new engine. However, it's a fine line between cost-saving and safety. The statement, "Won't know til teardown and inspection if wear has exceeded tolerances," underscores the critical importance of a thorough assessment. If wear has indeed exceeded tolerances, "only options are new/overhauled crank, or call it an iran and don't zero time the engine." This implies that "iran" might be a label for an overhaul where certain critical components, like the crankshaft (which can cost anywhere from "$8k to $20k depending on variant and availability"), are not replaced or zero-timed, making it a less comprehensive, but more affordable, option.Key Components and Decisions in an "Iran'ed" Engine

An "engine iran" process involves meticulous inspection and strategic component replacement. Unlike a full rebuild where almost everything is replaced, this approach targets specific wear items. For example, "Most people would not overhaul cylinders when doing an engine overhaul, They would replace them, though this is not a requirement." This indicates a common practice of replacing rather than overhauling cylinders, yet an "iran" type of overhaul might opt for a more selective approach. The data also provides a vivid example of critical component failure: "Jim said his a&p recently pulled a cylinder because it had a leaking exhaust valve, With the jug removed, the mechanic discovered a badly worn cam lobe and showed it to jim, explaining that the engine would need to be removed from the airplane and have its crankcase split in order to replace the damaged cam." Such findings necessitate significant work, potentially leading to an "iran" designation if a full zero-time rebuild is not pursued. The comprehensive nature of these inspections is critical. "The engine was checked over pretty thoroughly, and had all the seals replaced as part of that work." This level of detail ensures that even if the engine isn't "zero-timed," it is made safe and reliable for continued operation. Experts like JD, who has "15 years of experience in piston aircraft engines" and is "the owner of pinnacle aircraft engines, a 145 repair station," would be invaluable in making these critical decisions, sharing "stories of the various findings discovered during engine inspection." The goal is to address immediate issues and extend serviceable life, often including "Alt, air pump, prop governor, mags done," and ensuring components like the "lightweight starter" are in good order. This pragmatic approach to engine maintenance is a hallmark of the "engine iran" concept in aviation.Iran's Drive for Indigenous Engine Manufacturing

Beyond the specific aviation overhaul term, "engine iran" broadly refers to the significant strides Iran has made in developing and manufacturing its own engines. Faced with international sanctions and a strategic imperative for self-reliance, Iran has invested heavily in domestic capabilities across various engine types. This push is not merely about production; it's about establishing a robust industrial base that can meet the country's diverse needs, from military applications to civilian transportation and industrial machinery. The development of indigenous engines represents a critical component of national security and economic independence, reducing reliance on foreign suppliers and fostering local expertise. This strategic direction is driven by a long-term vision to overcome external pressures and build a resilient, self-sufficient industrial ecosystem.Pioneering Jet Engines: The Tolou Project

A crowning achievement in Iran's indigenous engine development is the "طلوع (Tolou, dawn)" project. As highlighted in the data, Tolou "is one of the first indigenously produced jet engines in iran." This is not merely a technical feat but "represents a significant step in iran's development of domestic aerospace technology." Developing a jet engine requires immense scientific, engineering, and manufacturing capabilities, encompassing advanced metallurgy, complex thermodynamic design, and precision manufacturing. The successful production of Tolou signifies Iran's ability to master these intricate processes, laying the groundwork for future advancements in its aviation and defense sectors. This project underscores a strategic commitment to self-sufficiency in critical aerospace components, ensuring that Iran can develop and maintain its aerial capabilities independently, despite external challenges. The Tolou project is a testament to the nation's determination to achieve technological sovereignty in a highly complex and strategic domain.Commercial and Industrial Engine Development

While jet engines capture headlines, Iran's indigenous engine manufacturing extends significantly into the commercial and industrial sectors, addressing the nation's fundamental transportation and energy needs. The data emphasizes the importance of "Automotive engine is an engine widely used in heavy commercial vehicles such as trucks, trailers and buses." This highlights a critical area of focus. The "engines produced by iranian diesel engine manufacturing company, based on the standards defined by the german daimler company and with confidence in the excellence and quality of these products, are a reliable point in responding to the country's transportation needs in the category." This demonstrates a commitment to quality and adherence to international standards, building trust in domestically produced engines for vital sectors. The emphasis on heavy commercial vehicles points to the backbone of a nation's logistics and infrastructure, making reliable domestic engine production essential for economic stability and growth. This broad focus ensures that the benefits of indigenous manufacturing permeate various aspects of daily life and industry.The Role of Private Sector and State Enterprises

The development of Iran's engine industry is a collaborative effort involving both state-owned enterprises and a burgeoning private sector. This dual approach leverages the strategic direction and resources of the state while harnessing the innovation and efficiency of private companies. The data explicitly states that "Farafan is the first and only private sector company in iran engaged in engine manufacturing." This is a significant detail, indicating a shift towards empowering private entities in a traditionally state-dominated industry. Farafan's success model is particularly noteworthy: "Success was achieved by concentrating managerial and technical aspects at farafan and subcontracting part production to other domestic companies, thereby making most efficient use of both capital and available manufacturing capacity." This hub-and-spoke model allows for specialization, efficient resource allocation, and the broader engagement of the domestic industrial base. Over time, other entities like "Saha became an important part of iran’s aviation industry," suggesting a growing ecosystem of specialized companies contributing to the overall strength of Iran's engine and aviation sectors. This blend of public and private initiatives is crucial for fostering competition, driving innovation, and building a sustainable industrial base capable of producing advanced "engine iran" technologies.Navigating Challenges: Sanctions and Sustainability

Iran's ambition to become self-sufficient in engine manufacturing is not without significant challenges, primarily stemming from international sanctions and the global imperative for environmental sustainability. The data hints at these difficulties, mentioning the "Department of the treasury, a front company that has carried out covert procurement." This illustrates the complex and often clandestine methods required to acquire necessary components or technologies due to sanctions, which can impede progress and increase costs. Despite these hurdles, the drive for domestic production remains strong. Furthermore, the global shift towards environmental sustainability and reduced fossil fuel dependency adds another layer of complexity. The data highlights this universal concern: "تقاضای روز افزون استفاده از وسایل نقلیه در دهه های اخیر از یک سوی و منابع محدود سوخت های فسیلی و افزایش آلاینده های زیست محیطی از سویی دیگر موجب شده تا تلاش های گسترده ای در." This translates to a growing demand for vehicles alongside limited fossil fuel resources and increasing environmental pollutants, necessitating extensive efforts in engine design. Iran, like other nations, must navigate these environmental pressures, striving to develop more fuel-efficient and less polluting engines. This involves investing in research and development for alternative fuels, hybrid technologies, and advanced combustion processes, ensuring that their indigenous "engine iran" solutions are not only robust but also environmentally responsible and competitive on a global scale.Beyond Physical Engines: A Note on "Search Engine Iran"

While the primary focus of this article is on physical engines and their manufacturing or overhaul, it's important to briefly address another interpretation that appears in the provided data: "موتور جستجو، به معنای “Search Engine” در انگلیسی، نرمافزاری است که به کاربران اجازه میدهد تا با جستجوی کلمات کلیدی، صفحات وب مرتبط با آن کلمات را پیدا کنند." This clearly refers to internet search engines. The data also lists "لیست موتورهای جستجوی ایرانی ایرانی. 1: گردو. گردو یه فراجستجوگر (meta search engine) است.یعنی نتایج اولیهی خود رو از موتور جستجوهایی نظیر گوگل میگیره و بعد از کامل کردن اطلاعات و بهبود آن، به کاربر نمایش میده." This highlights the existence and nature of Iranian search engines like Gerdoo, which acts as a meta-search engine. While these are also "engines" in a digital sense and represent Iran's efforts in technological self-reliance in the digital sphere, they are distinct from the mechanical and aerospace engines discussed at length. This article primarily concerns the physical "engine iran" due to the overwhelming context of the provided data points related to aircraft and commercial vehicle engines. However, acknowledging this digital dimension completes the picture of Iran's diverse technological pursuits.Conclusion: The Enduring Power of "Engine Iran"

The term "engine iran" is richer and more complex than it first appears. It encompasses both a specific, practical approach to aircraft engine maintenance and the ambitious, strategic drive of a nation to achieve self-sufficiency in manufacturing a wide array of powerplants. From the meticulous process of an "iran'ed" overhaul that extends the life of critical aviation components, to the pioneering development of indigenous jet engines like Tolou and the robust production of diesel engines for heavy commercial vehicles, Iran's commitment to mastering engine technology is evident. Despite the significant challenges posed by international sanctions and the global imperative for sustainable development, Iran continues to invest in its domestic engine industry, fostering both state-led initiatives and private sector innovation. This multifaceted effort underscores a broader national aspiration for technological independence and economic resilience. Whether referring to the precise work of an aviation mechanic or the grand scale of national industrial development, "engine iran" symbolizes a persistent pursuit of power, reliability, and self-reliance. We hope this exploration has provided valuable insights into the diverse meanings and implications of "engine iran." What are your thoughts on Iran's journey towards engine self-sufficiency, or your experiences with specific engine overhaul practices? Share your perspectives in the comments below, or explore our other articles on aerospace technology and industrial innovation. Your insights help us continue to provide comprehensive and engaging content.

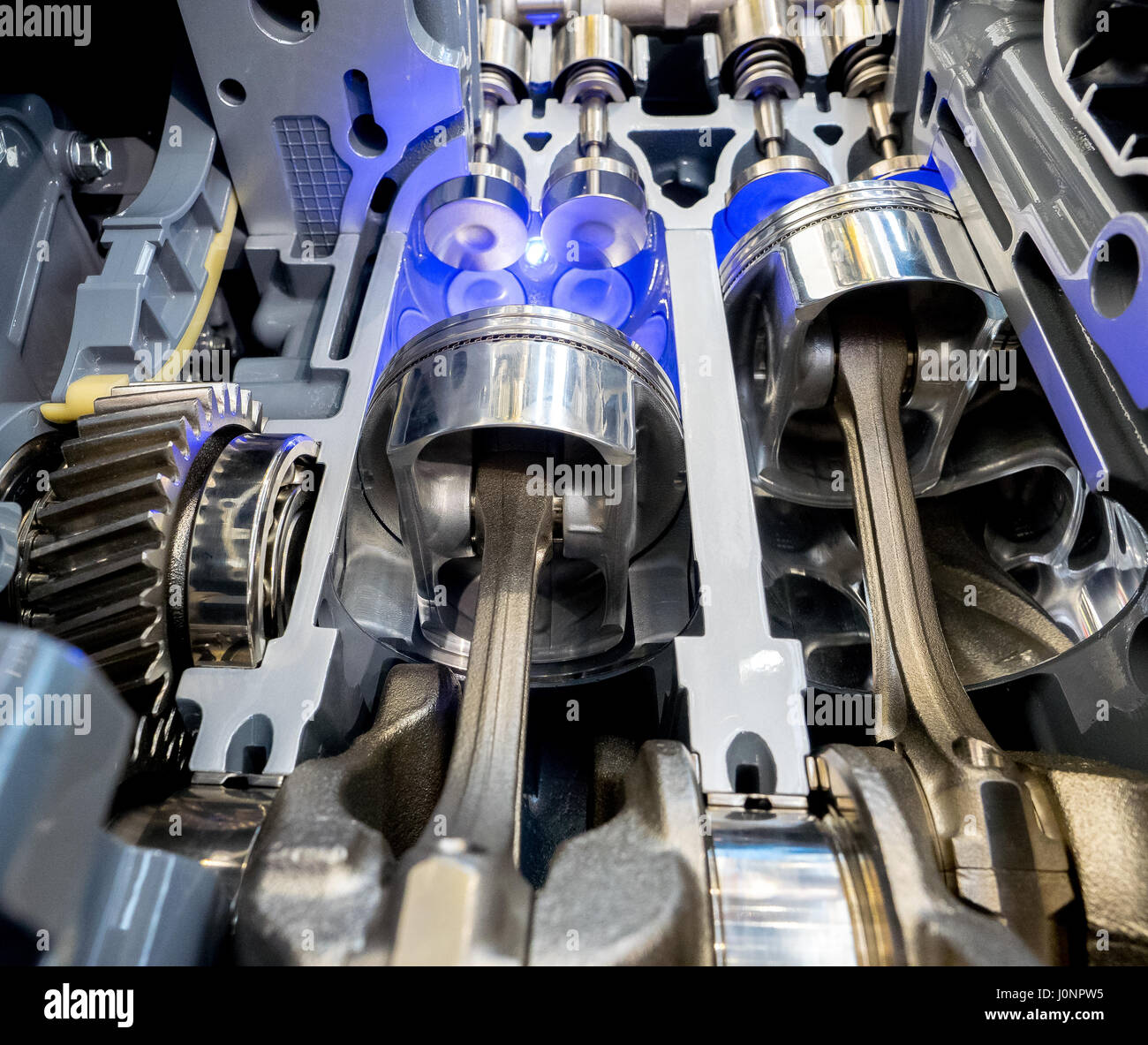

Inside view of engine, close up detail of two pistons in cylinder Stock

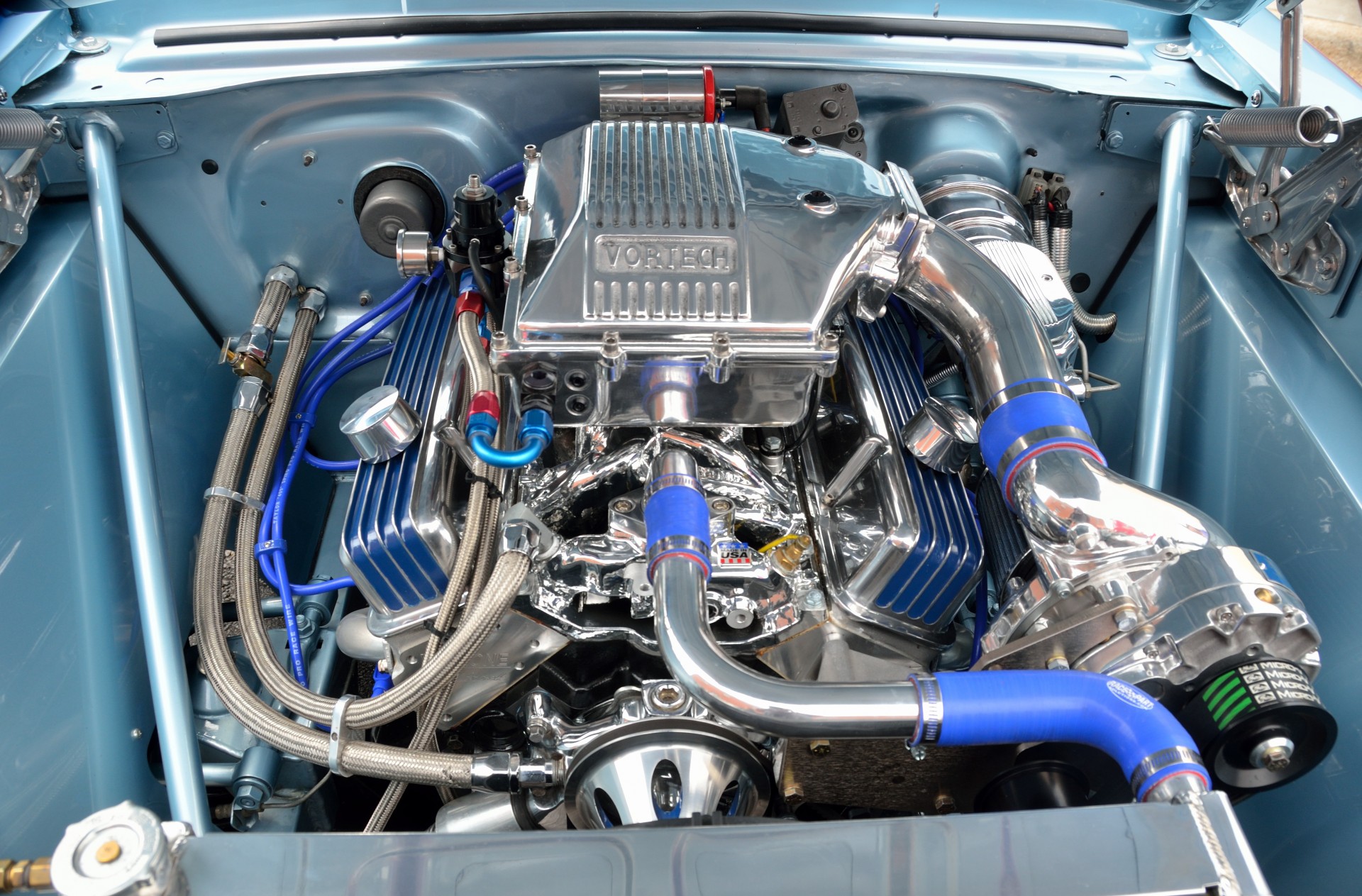

Car Engine Free Stock Photo - Public Domain Pictures

How It's Made Car Engines ~ sciences-howitsmade